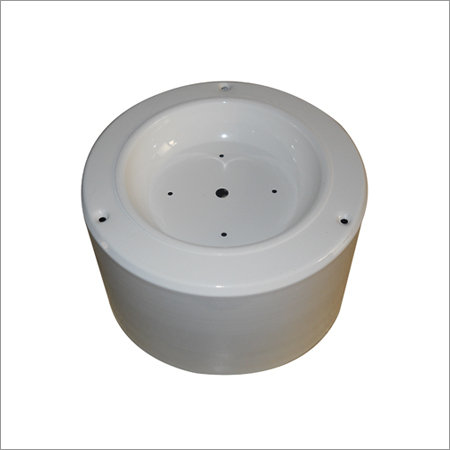

Aluminium Cast Venturies

Aluminium Cast Venturies Specification

- Product Type

- Venturi

- Material

- Aluminium

- Type

- Cast

- Shape

- Tapered/Conical

- Technique

- Die Casting

- Surface Treatment

- Smooth/Sand Blasted Finish

- Standard

- Industrial/Custom Specifications

- Outer Diameter

- Customizable (commonly 35 mm to 120 mm)

- Length

- 100 mm to 300 mm

- Inside Diameter

- Customizable (commonly 25 mm to 100 mm)

- Wall Thickness

- 3 mm to 12 mm

- Grade

- ADC12 / LM6 / Equivalent

- Size

- As per drawing / Standard sizes

Aluminium Cast Venturies Trade Information

- Minimum Order Quantity

- 25 Units

- Supply Ability

- 500 Units Per Week

- Delivery Time

- 2 Week

About Aluminium Cast Venturies

Backed by our rich industry experience, we are involved in manufacturing, supplying and exporting superior finish Aluminium cast venturies. In order to attain complete customer satisfaction, these venturies are manufactured using high grade raw materials and other components that are obtained from trusted vendors of the market. These venturies are designed into various lengths and specifications as per the needs of clients. Aluminium cast venturies are delivered to clients at market leading prices.

Features:

-

Corrosion & abrasion resistance

-

Fine finish

-

Sturdy construction

-

Longer service life

Precision-Engineered for Versatility

Our aluminium cast venturies are customized to meet specific industrial requirements. With the flexibility in sizes, wall thickness, and finishes, each product is engineered for superior strength, optimized flow, and longevity. The use of premium aluminium alloys ensures durability, corrosion resistance, and consistent performance in diverse applications.

Custom Manufacturing and Support

From initial design consultations to timely delivery, our team supports every stage of the process. Whether you need standard dimensions or have unique project requirements, our advanced die casting technique allows the creation of venturies to exact industrial or custom specifications. Our expert engineers ensure every detail matches your specifications.

FAQs of Aluminium Cast Venturies:

Q: How are aluminium cast venturies manufactured?

A: Aluminium cast venturies are produced using precise die casting techniques, where molten aluminium (ADC12, LM6, or equivalent) is poured into a mold shaped to the required dimensions. This process ensures accurate shapes, consistent wall thicknesses, and the option for smooth or sandblasted finishes.Q: What applications are aluminium cast venturies suitable for?

A: These venturies are widely used in industrial processes for controlling or measuring fluid and gas flows, especially in systems requiring efficient pressure regulation and optimized directional flow. Industries like automotive, HVAC, and process engineering often use them.Q: When should I choose a customized venturi over a standard size?

A: Choosing a customized venturi is recommended when existing standard sizes do not align with your system specifications or when unique flow characteristics are needed for your process, ensuring optimal performance and integration.Q: Where do you supply and export aluminium cast venturies?

A: We are based in India and cater to clients locally and internationally. Our distribution network covers manufacturers, service providers, distributors, traders, and exporters across various industrial sectors.Q: What are the main benefits of using ADC12 or LM6 grade aluminium for venturies?

A: ADC12 and LM6 aluminium alloys offer excellent strength-to-weight ratios, high corrosion resistance, and good machinability. Their properties make the venturies durable, lightweight, and suitable for demanding industrial environments.Q: What surface treatments are available for your venturies?

A: We provide a choice between smooth and sandblasted finishes, both enhancing the venturis aesthetic and functional qualities, such as improved flow and easy maintenance.Q: How do I order aluminium cast venturies as per my requirements?

A: You can provide your detailed specifications or drawings, including required dimensions and material grade, to receive a tailored quotation and production plan from our team. We offer support for both standard and fully customized orders.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Venturi Category

SS Venturi

Price Range 100.00 - 500.00 INR / Unit

Minimum Order Quantity : 25 Units

Inside Diameter : Customizable as per requirement

Product Type : Other, Venturi Tube

Standard : Other, ASTM / DIN / IS Standards

Type : Other, Industrial Venturi

Steel Venturis Spare Parts

Price Range 100.00 - 500.00 INR

Minimum Order Quantity : 25

Inside Diameter : 18 mm

Product Type : Other, Venturi Spare Part

Standard : Other, IS 2062 / ASTM A36

Type : Other, Replacement Part

Venturis Spares

Price Range 100.00 - 500.00 INR

Minimum Order Quantity : 25

Inside Diameter : 6 mm to 60 mm

Product Type : Other, Venturi Spares

Standard : Other, ASTM

Type : Other, Machined Spare Part

GST : 29ACYPA4533A1ZP

|

KOHINOOR ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry