Blower Inlets

Blower Inlets Specification

- Product Form

- Welded/Formed Inlet Section

- Heat Resistance

- Yes

- Corrosion Resistant

- Yes, with protective coating

- Material Composition %

- Fe > 98%, C < 0.25% (for typical MS)

- Tensile Strength

- 410 MPa (typical MS)

- Diameter

- 100 mm to 1200 mm or as specified

- Size

- Standard and customized

- Recyclable

- Yes

- Coating Type

- Red Oxide Primer / Epoxy Paint

- Product Name

- Blower Inlet

- Steel Type

- Mild Steel (MS)

- Steel Product Type

- Fabricated Fittings

- Grade

- IS 2062 / Equivalent

- Shape

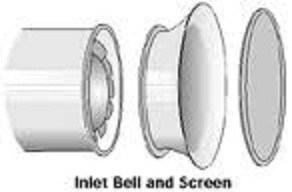

- Round/Rectangular/Inlet Bell

- Steel Standard

- IS, ASTM or as per request

- Surface

- Primer Coated / Painted

- Composition

- Primarily Iron with Carbon content per grade

- Application

- Industrial Air Handling, HVAC Systems, Ventilation, Dust Collection

- Dimension (L*W*H)

- Customized as per requirement

- Weight

- Varies based on size and material

- Color

- Grey / Customized

- Material Grade

- IS 2062 Gr A / IS 2062 Gr B

- Finish Type

- Smooth Painted

- Usage

- For Blower/Air Handling Equipment

- Manufacturing Process

- CNC Profile Cut, Bending, Welding

- Pressure Handling

- Suitable for low to medium pressure applications

- Adaptability

- Custom flanges and interfaces available

- Air Flow Compatibility

- Optimized for High Efficiency

- Connection Type

- Flanged / Welded

- Maintenance

- Minimal, easy to clean

Blower Inlets Trade Information

- Minimum Order Quantity

- 25 Pieces

- Supply Ability

- 500 Pieces Per Week

- Delivery Time

- 2 Week

- Main Domestic Market

- All India

About Blower Inlets

We are pleased to introduce ourselves as one of the leading manufacturers and exporters of superior quality Blower Inlets. These inlets are ideal for pressure applications to prevent dust & abrasive particles. Excellent quality raw materials and other components are used that are procured from certified vendors in the manufacturing process of these inlets. To meet the international quality standards, these inlets are thoroughly checked on various set parameters to ensure superior finish. We deliver these Blower Inlets in suitable packaging material to ensure safe transit.

Features:

-

Easy fitting

-

Dimensional accuracy

-

Fine finish

-

High performance

Versatile Applications in Industrial Air Handling

Blower Inlets are extensively used in HVAC systems, industrial ventilation, and dust collection setups. Their adaptability and custom sizing make them ideal for both new installations and retrofits, ensuring optimal air flow and system efficiency across diverse operational requirements.

Durable, High-Quality Construction

Each inlet is fabricated from superior mild steel (IS 2062 Gr A/B), utilizing CNC profile cutting, bending, and welding for precision and strength. The robust construction ensures long service life, reliable performance under low to medium pressures, and resistance to corrosion and heat up to 400C.

Customizable for Any System

Offering flexibility in dimensions and shapes (round, rectangular, inlet bell), these inlets can be tailored to fit any air handling setup. Flanged and welded connection types, along with various surface coatings and colors, provide solutions that align with unique project specifications.

FAQs of Blower Inlets:

Q: How is the Blower Inlet installed in industrial air handling equipment?

A: Blower Inlets can be installed using flanged or welded connections, tailored to match the equipments interface. The exact process depends on the systems requirements and may involve bolting to the blower flange or welding directly to the inlet section for a secure and leak-free integration.Q: What are the benefits of using CNC profile cut and welded construction for the Blower Inlet?

A: CNC profile cutting and welded construction ensure precise dimensions, smooth air passages, and strong joints. This results in improved airflow efficiency, durability, and minimal leakage, which are crucial for high-performance industrial applications.Q: When should I choose a custom size or flange for the Blower Inlet?

A: Custom sizes or flanges are recommended when standard dimensions do not fit your existing system or when unique operating conditions require specific interfaces. Providing precise measurements ensures seamless integration and optimal performance of your air handling equipment.Q: Where can these Blower Inlets be used within industrial applications?

A: These inlets are ideal for use in industrial air handling, HVAC systems, dust collection, and various ventilation applications. Their robust design and adaptability make them suitable for manufacturing plants, processing facilities, and large-scale commercial setups.Q: What makes these Blower Inlets easy to maintain and clean?

A: The smooth primer coated or painted surface minimizes dust adhesion, while the fabricated design ensures accessible internal sections. This simplifies routine maintenance and reduces downtime for thorough cleaning, supporting operational efficiency.Q: How do the protective coatings enhance the products durability?

A: Coatings such as red oxide primer or epoxy paint provide a protective barrier against corrosion and mild chemical exposure. This extends the products service life, especially when operating in humid or corrosive environments.Q: What is the process for ordering customized Blower Inlet dimensions or interfaces?

A: To order a customized Blower Inlet, you can specify the required dimensions, flange type, and coating preferences during the inquiry or quotation process. Manufacturers use this information to design and fabricate a solution that meets your exact operational needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Impeller Cones & Inlets Category

Dust Collector Support Cages

Minimum Order Quantity : 10 Pieces

Thickness : 2 mm 6 mm (wire thickness)

Diameter : 100 mm 300 mm

Surface : Galvanized, Epoxy coated, Powder coated

Steel Type : Other, Mild Steel / Stainless Steel

Fan Inlets

Price Range 100.00 - 500.00 INR / Piece

Minimum Order Quantity : 25 Pieces

Thickness : 1 mm to 3 mm

Diameter : 100 mm to 1250 mm (as per design)

Surface : Smooth/Coated

Steel Type : Other, Galvanized Steel

Impeller Cone

Price Range 100.00 - 500.00 INR / Piece

Minimum Order Quantity : 25 Pieces

Thickness : 5 mm to 20 mm

Diameter : 150 mm to 400 mm (customizable)

Surface : Smooth Machined Finish

Steel Type : Other, Mild Steel / Carbon Steel / Stainless Steel

GST : 29ACYPA4533A1ZP

|

KOHINOOR ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry