Dust Collector Support Cages

Price 250 INR/ Piece

Dust Collector Support Cages Specification

- Tensile Strength

- 370-630 MPa

- Product Form

- Cylindrical cage

- Hardness

- Depends on material, typically 120-180 HB

- Diameter

- 100 mm - 300 mm

- Recyclable

- Yes

- Size

- Standard and custom sizes available

- Heat Resistance

- Up to 450C (varies by grade and coating)

- Coating Type

- Zinc, epoxy, powder coating options

- Corrosion Resistant

- Yes, with surface treatment

- Material Composition %

- Depends on selected steel (e.g., 99% Fe in MS)

- Product Name

- Dust Collector Support Cages

- Steel Type

- Mild Steel / Stainless Steel

- Steel Product Type

- Wire cage, welded construction

- Grade

- Available in SS304, SS316, MS, GI

- Thickness

- 2 mm - 6 mm (wire thickness)

- Shape

- Round, Oval, Star

- Steel Standard

- ASTM / IS standards

- Surface

- Galvanized, Epoxy coated, Powder coated

- Composition

- Carbon steel or stainless steel composition

- Application

- Dust collection systems, Baghouse filter cages

- Dimension (L*W*H)

- Customizable as per requirement

- Weight

- Variable, depends on dimensions and wire gauge

- Color

- Silver, Black or as per coating

- Material Grade

- Industrial grade

- Finish Type

- Smooth, anti-corrosive finish

- Usage

- Support structure for dust filter bags

Dust Collector Support Cages Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About Dust Collector Support Cages

Competitive Advantages & Application Areas

Dust Collector Support Cages stand out as reliable, corrosion-resistant, and heat-resistant solutions for industrial dust collection systems. Their competitive advantages include smooth anti-corrosive finishes, high tensile strength, custom and OEM compatibility, and flexible sizing. These cages are ideally used in baghouse filter systems across manufacturing, power plants, and processing industries. Installation is simplified by easy mounting features, while low maintenance ensures consistent long-term use. Choose our cages for both new installations and retrofit applications.

Payment Terms, Export Markets & FOB Port

We offer competitive list pricing with flexible supply and valuation models tailored for distributors and exporters. Payment terms are negotiable to accommodate client requirements, with major export markets including Asia, Europe, the Middle East, and Africa. Products are shipped via leading FOB Ports in India, ensuring prompt and reliable supply for global clients. Our commitment to quality and transparency makes us a trusted partner for dust collection cage solutions worldwide.

FAQs of Dust Collector Support Cages:

Q: How does the installation process work for Dust Collector Support Cages?

A: Installation is straightforward using the provided collar or base, designed for easy mounting on both OEM and custom baghouse models. Detailed instructions are available to ensure a secure fit.Q: What are the main benefits of choosing a cage with specified wire thickness and coating?

A: Selecting proper wire thickness (2 mm - 6 mm) and coatings such as zinc, epoxy, or powder adds durability, enhances corrosion resistance, and extends cage life, even in harsh industrial environments.Q: When should I consider replacing my Dust Collector Support Cage?

A: Under normal use, these cages last 3-5 years. Replacement is recommended when signs of wear, reduced structural integrity, or filter bag performance issues are detected.Q: Where are these cages typically used?

A: Dust Collector Support Cages are utilized in industrial dust collection systems, especially within baghouse filter applications in factories, processing plants, and power generation facilities.Q: What is the process for ordering custom-sized cages?

A: Clients can specify dimensions, wire gauge, steel type, shape, and coating preferences. Minimum order quantity is set according to project needs, and detailed quotes are provided upon inquiry.Q: How does compatibility benefit operations with different baghouse models?

A: Our cages are engineered for direct compatibility with both OEM and custom baghouse designs, enabling seamless integration with various dust collection setups and ensuring system efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Impeller Cones & Inlets Category

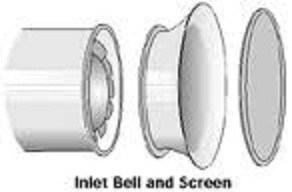

Blower Inlets

Price Range 100.00 - 500.00 INR / Piece

Minimum Order Quantity : 25 Pieces

Shape : Other, Round/Rectangular/Inlet Bell

Heat Resistance : Up to 400C (without special coatings)

Material Composition % : Fe > 98%, C < 0.25% (for typical MS)

Steel Product Type : Other, Fabricated Fittings

Fan Inlets

Price Range 100.00 - 500.00 INR / Piece

Minimum Order Quantity : 25 Pieces

Shape : Other, Round and Rectangular

Heat Resistance : Up to 200C

Material Composition % : Iron 98%, Zinc 2%

Steel Product Type : Other, Sheet Metal Formed

Impeller Cone

Price Range 100.00 - 500.00 INR / Piece

Minimum Order Quantity : 25 Pieces

Shape : Other, Conical

Heat Resistance : Up to 400C (material dependent)

Material Composition % : Fe (7098%), C (0.21.2%), Cr (1019%), Ni (014%)

Steel Product Type : Other, Machined Component

GST : 29ACYPA4533A1ZP

|

KOHINOOR ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry